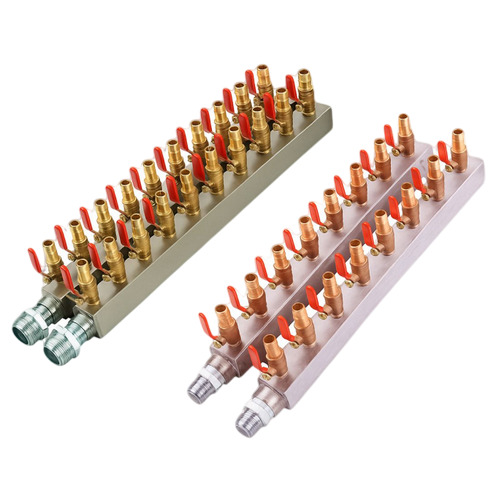

About Water Manifold (SS 4-IN - 4-OUT) Centralized Cooling Distribution

Discover the opulent efficiency of our Water Manifold (SS 4-IN - 4-OUT) Centralized Cooling Distribution system, crafted for stellar performance in injection moulding machines. Engineered with robust mild steel and finished in a sleek multi-colour palette, this system ensures blue-ribbon, centralized control and even distribution of cooling water. Explore competitive pricing and ephemeral downtime, transforming the way you manage mould temperature regulation. As a leading manufacturer and supplier in India, we deliver solutions that epitomize excellence and reliability for your industrial cooling needs.

Explore Premier Applications and Competitive Advantages

The Water Manifold (SS 4-IN - 4-OUT) shines in environments requiring centralized cooling flow management, such as injection moulding operations and large hydraulic systems. With a design emphasizing precise control and uniform temperature distribution, its usage elevates productivity and mitigates thermal stress on moulds. The systems competitive pricing, coupled with ephemeral installation time, positions it as an opulent choice for manufacturers seeking robust and efficient cooling solutions.

Quotations, Sample Availability, and Reliable Shipping

Request a quotation for our Water Manifold (SS 4-IN - 4-OUT) to explore the asking price and sample availability. We ensure samples are meticulously packed, utilizing secure shipping to safeguard your investment during transit. Our packaging is tailored for both domestic and international exports, with main markets spanning Asia, the Middle East, and Africa. Experience the assurance of prompt delivery, responsive support, and stellar packaging standards from a trusted Indian manufacturer.

FAQs of Water Manifold (SS 4-IN - 4-OUT) Centralized Cooling Distribution:

Q: How does the Water Manifold (SS 4-IN - 4-OUT) enhance cooling distribution in moulding applications?

A: The Water Manifold ensures efficient, centralized distribution of cooling water, maintaining uniform temperature throughout injection moulds and enhancing production quality.

Q: What processes does this manifold support in industrial environments?

A: It facilitates centralized cooling flow management in moulds and hydraulic systems, supporting stable and precise temperature regulation essential for large-scale manufacturing operations.

Q: Where can the Water Manifold (SS 4-IN - 4-OUT) be installed?

A: This manifold is suitable for injection moulding plants, industrial facilities handling hydraulic systems, and any application where uniform temperature control is required.

Q: What are the competitive advantages offered by this product?

A: Competitive pricing, durable mild steel construction, ephemeral installation downtime, and stellar performance make this manifold a blue-ribbon solution for industrial cooling control.

Q: Is a product sample available before placing a bulk order?

A: Yes, product samples are available upon request, and you can obtain a quotation to review pricing and specifications before making a decision.

Q: How is the product packaged for export and what markets are served?

A: The manifold is securely packaged using robust materials for safe shipping, with main export markets including Asia, the Middle East, and Africa.